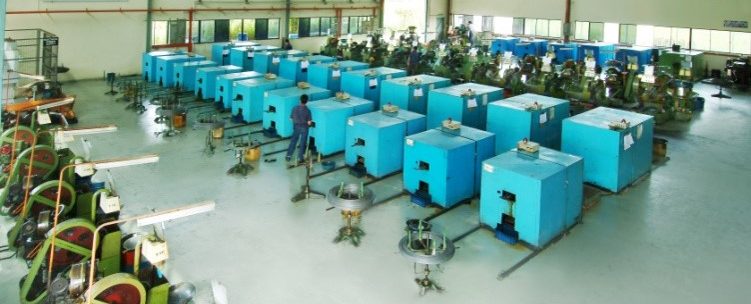

Manufacturing

With 28 heading machine, 21 thread roller machine and 4 SEMS machine, our manufacturing capacity is up to 1,400,000 pieces per 8 hours of operation daily.

This will make sure we have the capability to meet our customer’s demand in the shortest time possible.

Quality Control

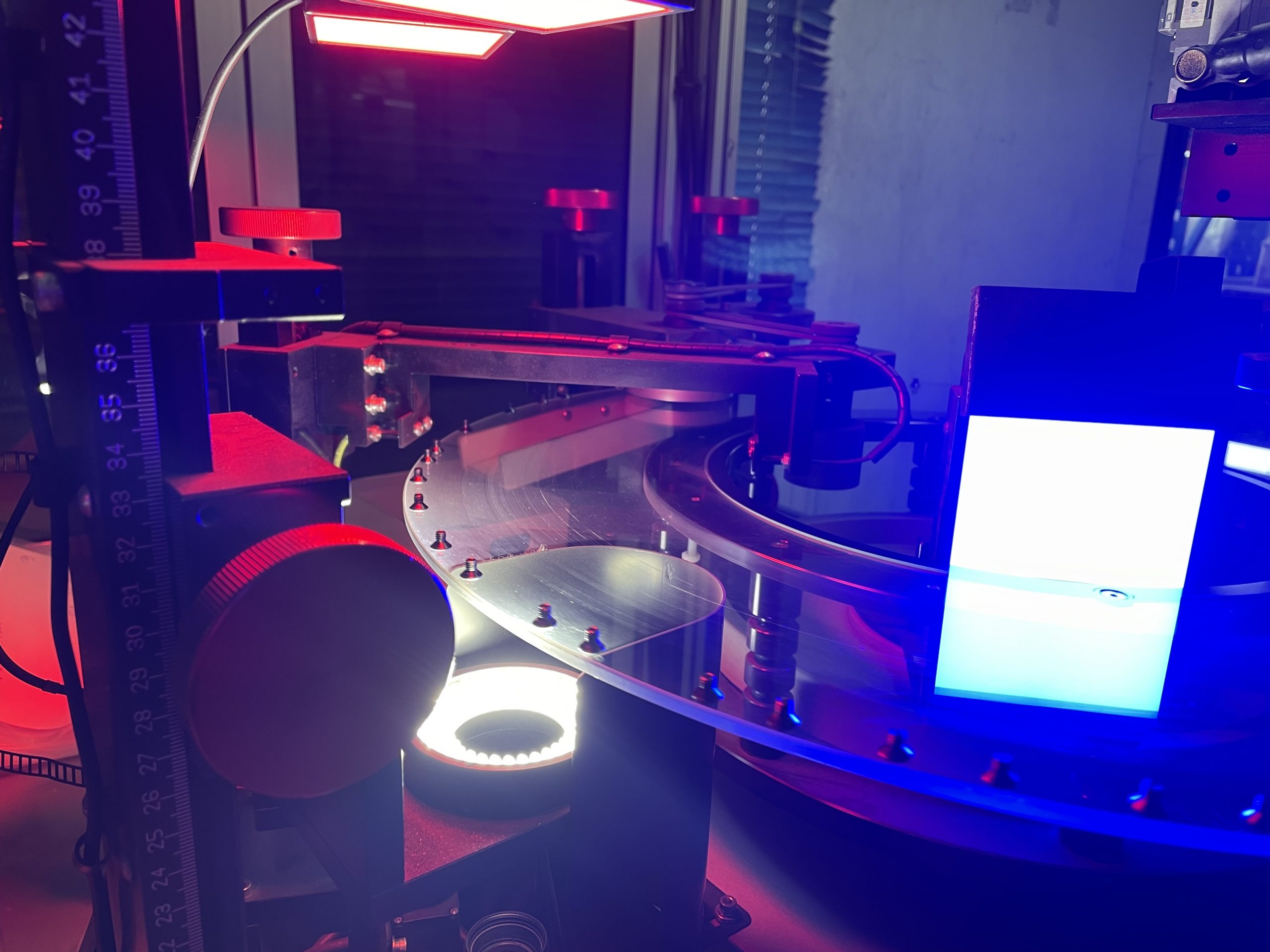

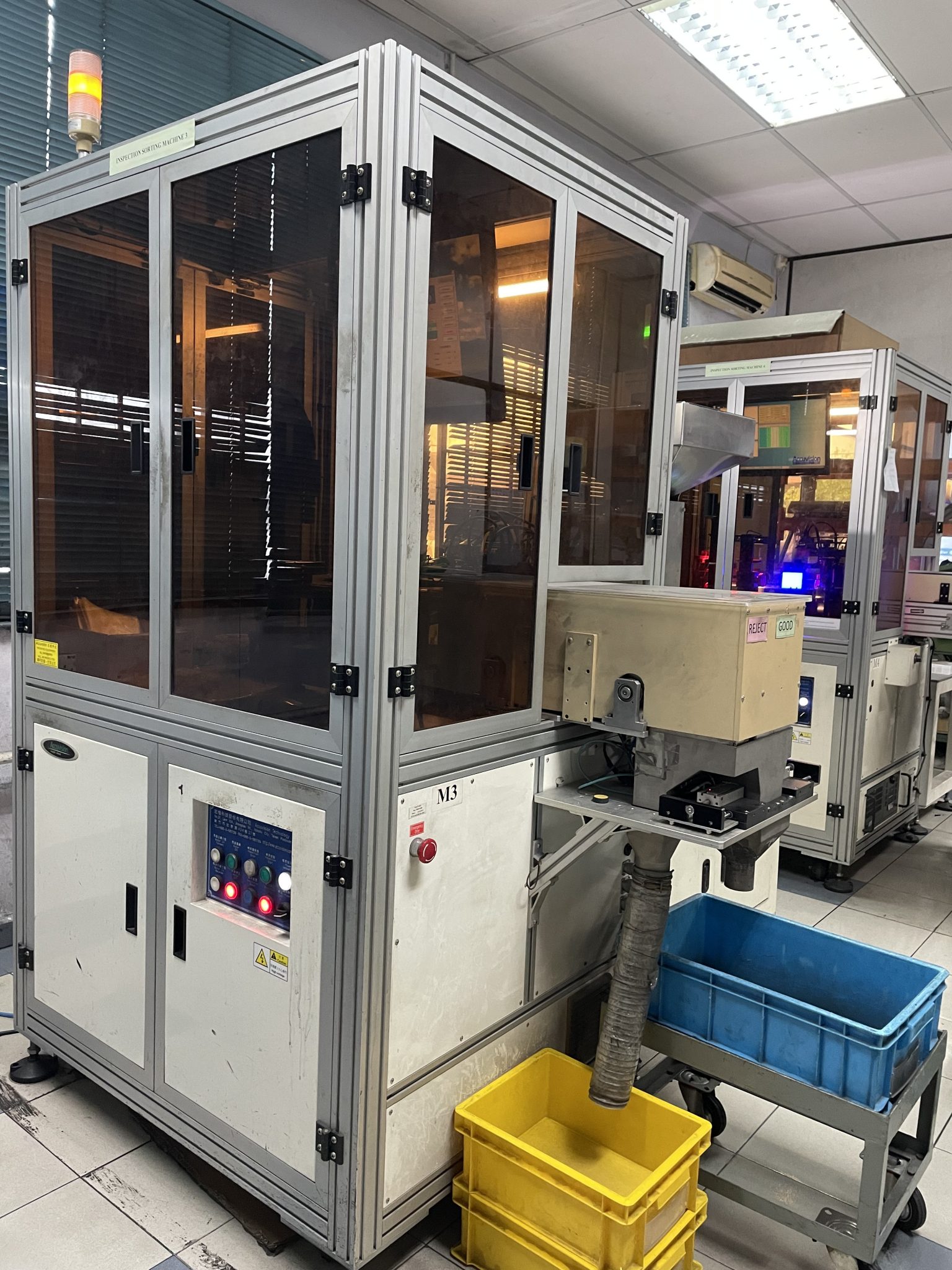

SORTING MACHINE

Usage of sorting machine to speed up as well as minimise human error during the sorting process of thousands upon thousands of fasteners that we processed everyday in the quality control department.

With the assist of sorting machine, we are able to minimise faulty product delivered to our customers.

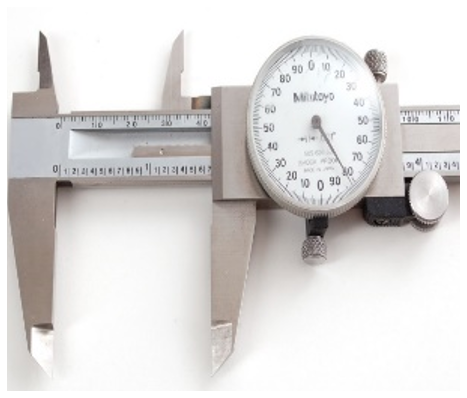

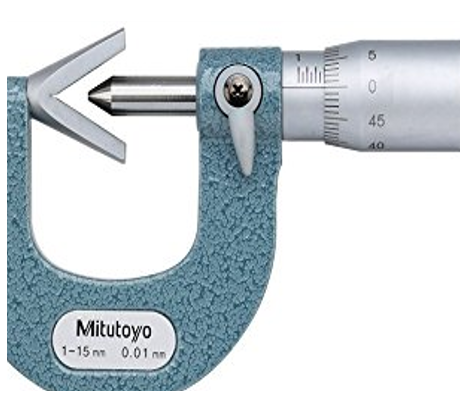

MANUAL MEASUREMENT TOOLS

In our commitment to deliver the best product quality to our customers, we also implement manual measurement in our quality control department. This perfectly offset the incapabilities of sorting machine as well as sometimes the marginal error by the sorting machine.

We only used calibrated tools in the department to make sure our products meets the specification of customers.

A visual inspection process is also carried out by our experienced team before we pack and deliver the product to our customers.

SALT SPRAY TEST

Salt spray test is a standardised and popular corrosion test method, used to check corrosion resistance of materials and surface coating.

This additional test was done in-house to make sure that our product delivered to our customers are in their best coating condition to prevent rusting process while the products are sitting idle in our warehouse waiting for delivery and/or in our customers’ warehouse waiting to be used.

Warehouse

We are also committed to delivery our products to our customers on a timely manner.

We have prepared a storage warehouse facility to store our stocks so when our customers request for a delivery of product, we are able to provide to meet their production timeline.